- Welcome to PACKMAGE

-

Language: English

- Login

- Create your ID now

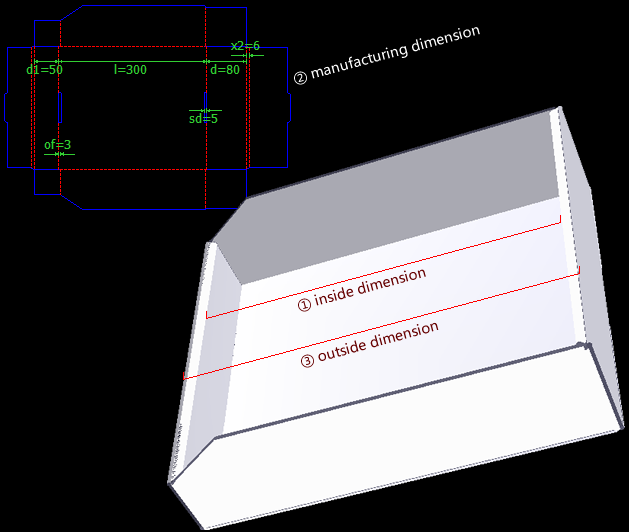

We can make structural design in different size modes in PackMage, it's very useful for designers in different industries.

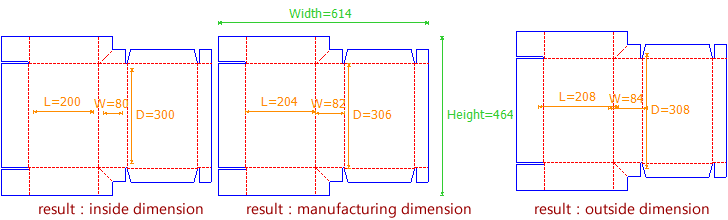

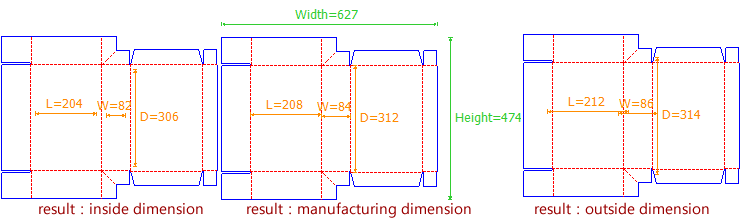

| Inner size | Good's size combined with cushioning material's size is the min size of the package. In inner size mode, the only things we have to know is the size of the packed product and the caliper of board we have chosen, other things? let's hand them over to PackMage. |

| Outer size | If we do the jobs in logistics or pack transportation, outer size mode is recommended. At this situation, we often know the most economical size of the package, which equals to the outer size in PackMage. In outer size mode, we can get the structural design immediately. |

| Die-cut size | Size for die-cutting process. Print industry, proof industry and die cut manufacturers, which product packages, usually choose die-cut mode. |

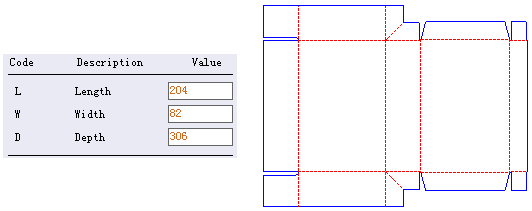

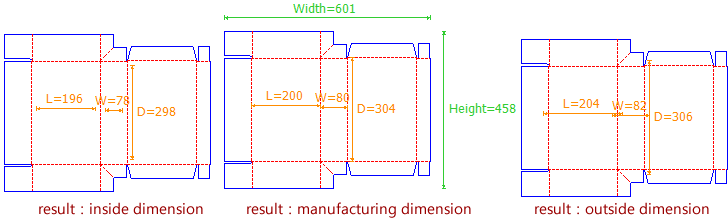

Take template D023 for example, let's analyse the different means and values from the same parameter in structural design.

The size of box remains unchanged(caliper=2mm, in-Loss=1mm, out-Gain=1mm)

Actually, three pictures below is the same box structure by export in different size modes. The same as following.

PACKMAGE TECHNOLOGY CO.,LIMITED