- Welcome to PACKMAGE

-

Language: English

- Login

- Create your ID now

They are generated by folding action. A board with length 40cm and caliper 2cm for example:

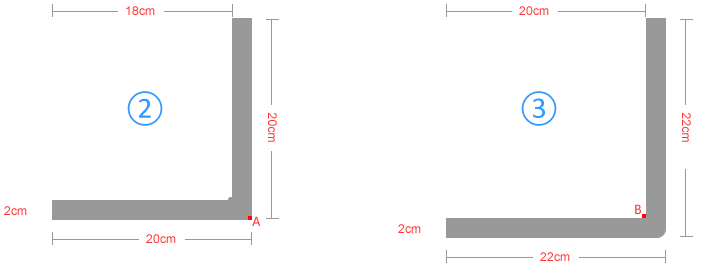

Die cut the board, and bent it into a right angle. There are 2 kinds of misunderstanding which are very popular:

But the right thing is like this:

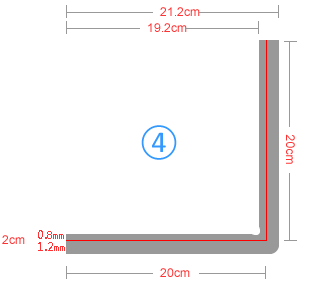

Because of the property of board, after die-cut the board, the folding axis is neither inside line(B in figure③) nor outside line(A in figure②). It's some line between A and B(C in figure④). Distance between A and C is always half the caliper, but sometimes it's not.

In this example, distance between A and C is 0.8cm, BC is 1.2cm. In practice, we called AC(0.8cm) as in-Loss, and BC(1.2cm) as out-Gain. We can also calculate that the inner size of box equals to 20cm - 0.8cm=19.2cm, and the outer size is 20cm + 1.2cm = 21.2cm

Maybe someone questions the use of this theory. Well, it's very important in actual production:

PACKMAGE TECHNOLOGY CO.,LIMITED